- View Mobile Number

iirtdelhi@gmail.com

Microbiological Testing / Studies

Leading Manufacturers, Exporters, Wholesaler, Retailer of Bacterial Endotoxin Testing, Bacterial Endotoxins Testing Services, Bio Pesticides Testing Services, Bioburden Testing Services, Biopesticides and Biofertilizers Testing Services, Cosmetic Testing Services, Daphnia SP. Acute Immobilisation Test, Drug Testing Service, Freshwater Alga and Cyanobacteria, Growth Inhibition Test, Herbal Product Testing Service, Medical Device Testing Service, Microbial Limit Test Service, Pathogen Testing Services, Rapid Kit Testing, Rapid Test Kit Service, Sanitary Napkin Testing Service, Sterility Testing Services, Surgical Products Testing Services and Water Testing Services from Ghaziabad.

The Bacterial Endotoxins Test (BET), also known as the Limulus Amebocyte Lysate (LAL) test, is a microbiological assay used to detect and quantify endotoxins — toxic components of the outer membrane of Gram-negative bacteria — in pharmaceutical products, medical devices, and biologicals. Endotoxins can cause severe inflammatory responses if introduced into the body, so their levels must be strictly controlled.

The ability to detect all environmental Gram-negative bacterial endotoxins is a critical element of safe parenteral production and implantable medical device manufacturing. With over 80 million endotoxin tests performed annually, these medical techniques, treatments, and therapies sustain the lives of thousands of patients, requiring a highly sensitive and exquisitely specific in vitro assays to ensure their quality and safety for release.

The Bacterial Endotoxins Test (BET), commonly known as the Limulus Amebocyte Lysate (LAL) test, is a vital microbiological assay used to detect and measure endotoxins—harmful substances found in the outer membrane of Gram-negative bacteria. These endotoxins can trigger serious inflammatory reactions, including fever, shock, or even organ failure when introduced into the human body.

BET is routinely performed on pharmaceutical products, biologicals, and medical devices, especially those intended for injection or direct contact with blood or internal tissues. The test uses the blood cells of the horseshoe crab (Limulus polyphemus), which react in the presence of endotoxins, allowing accurate detection and quantification.

Controlling endotoxin levels is critical to ensure patient safety and regulatory compliance. The BET is recognized by pharmacopeias worldwide (e.g., USP, EP, JP) and is an essential step in quality control to prevent contamination and ensure the sterility and safety of healthcare products.

Biopesticides and biofertilizers are agricultural products derived from beneficial microorganisms that help improve crop productivity and provide natural pest control. These microbial-based inputs offer a sustainable and eco-friendly alternative to chemical pesticides and fertilizers. Biopesticides target specific pests without harming beneficial organisms, while biofertilizers enhance soil fertility and plant growth by promoting nutrient availability and uptake.

To ensure their effectiveness, safety, and regulatory compliance, microbiological testing is essential. This testing verifies the presence and viability of the intended microbial strains, checks for contamination by harmful microbes, and assesses overall product stability. It also ensures the products meet both national and international quality standards.

Accurate microbiological evaluation plays a crucial role in maintaining product quality, supporting certification, and building farmer confidence in bio-based agricultural solutions. These tests contribute to the safe application of biopesticides and biofertilizers, promoting healthier crops and sustainable farming practices.

Bioburden testing is a vital microbiological assay used to quantify the number of viable microorganisms present on or within raw materials, components, or finished products prior to sterilization. This testing is especially critical in industries such as pharmaceuticals, medical devices, and other sterile product manufacturing, where maintaining low microbial contamination levels is essential for product safety and regulatory compliance.

The purpose of bioburden testing is to assess the microbial load and ensure that sterilization processes are effective and appropriately validated. It also helps identify potential contamination sources in the manufacturing environment, allowing for better process control and quality assurance.

Bioburden testing typically involves sample collection, extraction, filtration, and microbial culturing to count colony-forming units (CFUs). The results support decisions on sterilization methods, cleaning procedures, and routine monitoring, ultimately helping to ensure that products meet stringent safety and efficacy standards before reaching the market.

Biopesticides and biofertilizers are microbial-based agricultural inputs that enhance crop productivity and pest control using natural, beneficial microorganisms. Microbiological testing ensures their efficacy, safety, and compliance with national and international standards.

Cosmetic testing is an essential process in the cosmetic industry aimed at ensuring product safety and quality. It focuses on verifying that cosmetics are free from harmful microorganisms and safe for consumer use. This testing involves the detection, identification, and quantification of microbial contaminants in various stages of production, including raw materials, in-process samples, and finished products.

Common microbial tests check for the presence of bacteria, yeast, and mold, as well as specific pathogens like Staphylococcus aureus, Pseudomonas aeruginosa, and Escherichia coli, which can pose serious health risks.

Routine cosmetic testing ensures compliance with regulatory standards and helps maintain product stability, shelf life, and consumer trust. By identifying contamination risks early in the manufacturing process, companies can take corrective actions, reduce product recalls, and ensure the safety and effectiveness of their cosmetic products before they reach the market.

This Test Guideline describes an acute toxicity test to assess effects of chemicals towards daphnids (usually Daphnia magna Staus).

Young daphnids, aged less than 24 hours at the start of the test, are exposed to the test substance at a range of concentrations (at least five concentrations) for a period of 48 hours. Immobilisation is recorded at 24 hours and 48 hours and compared with control values. The results are analysed in order to calculate the EC50 at 48h. Determination of the EC50 at 24h is optional. At least 20 animals, preferably divided into four groups of five animals each, should be used at each test concentration and for the controls. At least 2 ml of test solution should be provided for each animal (i.e. a volume of 10 ml for five daphnids per test vessel). The limit test corresponds to one dose level of 100 mg/L. The study report should include the observation for immobilized daphnids at 24 and 48 hours after the beginning of the test and the measures of dissolved oxygen, pH, concentration of the test substance, at the beginning and end of the test.

Drugs and pharmaceutical testing is a vital component of the pharmaceutical industry, ensuring that all products meet strict standards for safety, efficacy, and quality. This testing verifies that pharmaceutical products are free from harmful microorganisms and comply with acceptable microbial limits as defined by regulatory guidelines. It also assesses the effectiveness of sterilization and preservation methods, which are critical in preventing microbial contamination throughout a product 's shelf life.

Testing is conducted at various stages—raw materials, in-process samples, and finished products—to detect and quantify microbial presence, including bacteria, yeast, mold, and pathogenic organisms.

By conducting thorough microbial and quality testing, manufacturers can ensure product consistency, patient safety, and regulatory compliance. This process not only helps in identifying potential risks early but also supports the development of reliable and effective medications, minimizing the chances of product recalls or adverse effects in end users.

The purpose of this test is to determine the effects of a substance on the growth of freshwater microalgae and/or cyanobacteria. Exponentially growing test organisms are exposed to the test substance in batch cultures over a period of normally 72 hours.

The system response is the reduction of growth in a series of algal cultures exposed to, at least, five concentrations of a test substance. Three replicates at each test concentration should be used. The response is evaluated as a function of the exposure concentration in comparison with the average growth of control cultures. The cultures are allowed unrestricted exponential growth under nutrient sufficient conditions (two alternative growth media: t fluorescent illumination. Growth and growth inhibition are quantified from measurements of the algal biomass as a function of time. The limit test corresponds to one dose level of 100 mg/L. This study includes: the determination, at least daily, of the algal biomass; the measure of the pH (at the beginning and at the end); microscopic observation. This Test Guideline describes two response variables: average specific growth rate, and yield.

Herbal and AYUSH products (Ayurveda, Yoga, Unani, Siddha, and Homeopathy) are gaining widespread popularity in the health and wellness sector due to their natural and holistic approach. However, their natural origin makes them highly susceptible to microbial contamination, which can compromise product safety and efficacy.

Microbiological testing plays a vital role in ensuring these products are safe for human consumption and meet established regulatory quality standards. This testing involves the detection and quantification of harmful microorganisms such as bacteria, yeast, mold, and specific pathogens like E. coli, Salmonella, and Staphylococcus aureus.

By identifying microbial contamination early, manufacturers can take corrective actions to maintain product integrity, protect public health, and ensure compliance with national and international guidelines. Regular microbiological testing is essential for building consumer trust and promoting the safe use of herbal and AYUSH-based health products in the market.

Medical device microbiological testing is a vital process to ensure that medical devices are safe for use and meet strict regulatory standards. This testing is essential for both sterile and non-sterile devices, as it helps detect and control microbial contamination that could pose risks to patient health.

Key microbiological tests include:

-

Sterility testing – confirms that sterile devices are free from viable microorganisms.

-

Bioburden assessment – measures the number of microorganisms present on a device before sterilization.

-

Endotoxin testing – detects bacterial endotoxins that can cause fever or toxic reactions, especially in devices that contact blood or cerebrospinal fluid.

-

Cleanliness evaluation – ensures devices are free from residual contaminants, including organic and inorganic matter.

These evaluations are crucial for maintaining product safety, performance, and regulatory compliance, particularly for devices intended for invasive or long-term use.

The Microbial Limit Test is a vital microbiological assay used to evaluate the quantity and type of microorganisms present in non-sterile products such as pharmaceuticals, cosmetics, food, and raw materials. This test helps determine whether the microbial content of a product falls within the acceptable safety limits defined by regulatory standards.

The assessment includes both quantitative and qualitative analysis, targeting:

-

Total aerobic microbial count (TAMC)

-

Total yeast and mold count (TYMC)

-

Absence of specific pathogens, such as Escherichia coli, Salmonella spp., Staphylococcus aureus, and Pseudomonas aeruginosa

The purpose of the Microbial Limit Test is to ensure product safety, quality, and compliance by detecting microbial contamination that could pose health risks to consumers. This testing is crucial during product development, manufacturing, and quality control stages to prevent the release of contaminated products into the market.

The Pathogen Test is a vital microbiological assay used to detect the presence—or confirm the absence—of specific harmful microorganisms (pathogens) in a wide range of products, including pharmaceuticals, cosmetics, food, water, herbal products, and medical devices. This testing is essential to ensure product safety, consumer health, and regulatory compliance with national and international quality standards.

Common pathogens tested include Escherichia coli, Salmonella spp., Staphylococcus aureus, Pseudomonas aeruginosa, and Candida albicans, which can pose serious health risks if present. The test involves culturing techniques and biochemical or molecular methods to accurately identify these organisms.

Pathogen testing helps manufacturers identify contamination early in the production process, reduce product recalls, and maintain the safety and quality of their products. It is a critical component of Good Manufacturing Practices (GMP) and quality control procedures across multiple industries.

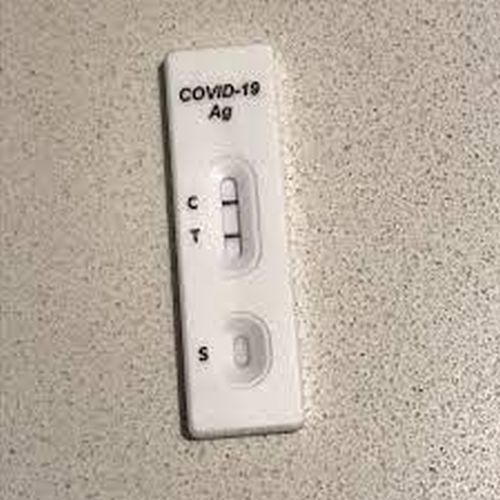

Rapid testing kits are designed to detect and quantify microorganisms quickly, often within minutes to a few hours, compared to traditional culture methods which may take 2–7 days. These kits are widely used in pharmaceuticals, food safety, water testing, clinical diagnostics, and environmental monitoring.

Rapid testing kits are advanced tools developed to quickly detect and quantify microorganisms, offering results within minutes to a few hours, as opposed to traditional culture methods that may require 2 to 7 days. These kits use technologies such as immunoassays, biosensors, molecular diagnostics (e.g., PCR), and fluorescence detection to deliver fast and accurate results.

They are widely utilized across various industries, including:

-

Pharmaceuticals – for ensuring product sterility and quality

-

Food safety – to detect contamination and prevent foodborne illnesses

-

Water testing – to monitor microbial presence in drinking and recreational water

-

Clinical diagnostics – for rapid disease detection and patient care

-

Environmental monitoring – to assess microbial risks in soil and air

Rapid testing kits improve efficiency, safety, and decision-making, making them invaluable for time-sensitive applications where early detection of microbial contamination is critical.

Sanitary product testing is a vital process that ensures personal hygiene products—such as sanitary napkins, tampons, diapers, baby wipes, adult incontinence products, and similar items—are safe, non-toxic, and free from harmful microorganisms. Given that these products come into direct or prolonged contact with the skin or mucosal surfaces, maintaining high microbial safety standards is essential to prevent potential infections, skin irritations, and allergic reactions.

Testing typically involves evaluating the microbial load, detecting pathogenic organisms, and ensuring the materials used do not release harmful substances upon contact. It also assesses parameters such as absorbency, pH levels, skin compatibility, and material integrity under normal use conditions.

By conducting thorough sanitary product testing, manufacturers can meet regulatory and quality standards, safeguard public health, and build consumer trust in the safety and reliability of their hygiene products.

Sterility testing is a vital microbiological quality control procedure used to ensure that sterile pharmaceutical products, medical devices, and other sterile preparations are completely free from viable microorganisms. This test is especially crucial for products intended for injection, ophthalmic use, implantation, or surgical procedures, where any microbial contamination could lead to serious health risks.

The process involves incubating product samples in nutrient-rich media under controlled conditions to promote the growth of any contaminating microbes. If no growth is detected after the incubation period, the product is considered sterile.

Sterility testing is required by regulatory authorities and follows stringent protocols, such as those outlined in pharmacopeial standards (e.g., USP, EP, or JP). It plays a critical role in safeguarding patient health by verifying that products meet strict sterility requirements before they are released to the market or used in clinical settings.

Surgical testing encompasses a range of procedures and evaluations designed to ensure the sterility, cleanliness, and overall safety of surgical instruments, environments, personnel, and products used during surgical procedures. The primary goal of these tests is to prevent surgical site infections (SSIs) and to support compliance with established healthcare regulations and safety standards.

Key aspects of surgical testing include microbial testing, sterility validation, residue analysis, and equipment performance checks. These assessments are conducted on surgical tools, sterile drapes, gloves, implantable devices, and the operating room environment to confirm that they meet safety and hygiene requirements.

Routine surgical testing helps identify and eliminate contamination risks, ensuring patient safety and successful surgical outcomes. It also supports hospital infection control programs and promotes adherence to protocols set by organizations such as the FDA, ISO, and WHO.

Microbiological testing of water is essential for evaluating its safety and quality by identifying the presence of harmful microorganisms. This testing focuses primarily on detecting bacteria, viruses, protozoa, and fungi that can pose significant health risks if consumed or used. It plays a vital role in preventing waterborne diseases and ensuring compliance with public health standards.

Microbiological analysis is widely applied in various sectors, including:

-

Drinking water testing – to ensure safe consumption

-

Wastewater treatment – to monitor and control microbial contamination before discharge

-

Environmental monitoring – for assessing water bodies like rivers, lakes, and reservoirs

-

Industrial applications – such as food and beverage processing, where water purity is crucial

Regular microbiological testing helps in the early detection of contamination and supports effective water treatment processes, making it a critical component of public health and environmental safety strategies.